By Ron Jones – builder and skipper of Freewind

The raw materials were a pile of metal sheets and strips, and a carton of welding rods.

After lots of work - planning, cutting, welding and grinding - sweating, and swearing, fabricating and fitting - more sweating, swearing, sanding, painting and varnishing, and a whole lot more - the pile of metal had transformed into a beautiful boat. After many highs and lows, frustrations and elations, she was finally ready for launching. Freewind - a boat that was to carry us, the Jones family, across many miles of ocean, through calms and storms and everything in between.

This is the story of how it all happened, in pictures.

To date, Freewind has logged close to 30,000 nautical miles across the southern Pacific Ocean and Tasman sea, with skipper Ron, first mate Dalia and crew Eleanor and Melanie.

Whangaparaoa, New Zealand, 1994

The hull was built “upside down”; here, the frames are all assembled and the first plates being put in place.

There was a lot of welding to be done. Here, I’m welding the hull plates and setting the framework for the keel.

The old Fordson Major tractor was a great workhorse. It was rigged as a mobile crane to lift the plates in place.

Finishing off the keel Ron and Dalia with the hull – ready to turn over

| The strange structures welded onto the hull are the “wheels” on which the hull is rolled to turn it upside down | At first, the hull was lifted with a truck jack, then, with the block-and-tackle on the tractor |

|  |

| This is as far as the “tractor-crane” could lift | Superman Ron - “look…one hand!” |

Starting to pull from the other side She’s rolling….

Almost there

The deck plates are lifted in place More fitting and welding…..

| I fabricated the cockpit structure in the workshop, now it’s being lifted into its place on deck | Here it is all fitted with winch mounts and dodger frame. In the foreground is the base for the mainsheet track. |

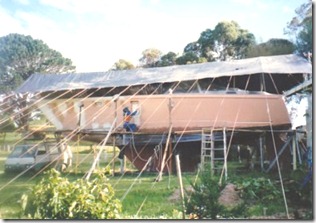

Sandblasting – this was the worst job in the whole process, especially blasting the inside of the hull, where the visibility was close to zero. The old Nissan van did its last service as a mobile scaffold before going to the scrap-yard. The sandblasting was done in sections; as soon as an area was sandblasted, the first coat of paint was sprayed on, while the steel was still squeaky clean – essential for a good steel paint job. These were marathon days, and always with an eye on the weather and any sign of humidity in the air.

|  | The first coat of paint is the green Zinc paint, which bonds with the freshly-sandblasted steel. Next come two coats of epoxy undercoat (the pink layer), which is being sprayed on the bow here. |

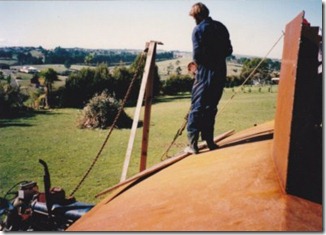

Fairing and smoothing the hull in preparation for the two white finish coats.

Painting all done – inside and out. It was now 1996, and daughter Eleanor was 18 months old

This is what the main cabin looked like during construction.

The Ford engine going in. I designed the back hatch so the engine would just fit through.

Moving Freewind

Now came the nerve-wrecking part – moving Freewind up the driveway to the road, and to the marina. As the driveway was very steep and the ground was wet, we had to get a heavy haulage truck to tow the boat-haulage truck up the hill.

| The Boat Haulage truck moving its rig under the boat. The tow truck is parked at the top of the driveway behind it. | The heavy tow truck started skidding as it pulled and had to be chained to a tree and winched for a few meters until reaching dry ground. |

| Yes, it was certainly nerve-wrecking, but everyone, including Freewind, made it safely up the hill. |  |

There goes my baby… fortunately, the marina was just down the hill. Freewind ready for launching in Gulf Harbour Marina

| The launching went really well – Freewind looked wonderful, bright, perfect, in the water for the first time. The mast was fitted and she was almost ready for her first ocean crossing. |  |

| Dolphins and Diamonds |

The End …but it’s really only the beginning

Hard job Rob, but with a lot of fun.

ReplyDelete